-

QPlease describe your role at Amorepacific.

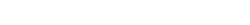

I am in charge of managing Amorepacific’s SCM production technologies. Our team identifies external production technologies to enhance our company's competitiveness and integrates them into our SCM production. We also undertake projects to develop new production technologies within the team.

-

QWhat does 'SCM' mean at Amorepacific?

Amorepacific is truly exceptional with its own laboratory, an 80-year history of production, and unique production technologies. These innovations and heritage enable us to create top-quality products that meet customer needs and deliver exceptional experiences.

Additionally, our expertise in producing customized cosmetics involves precise ingredient preparation, advanced production techniques, and sophisticated packaging technologies. These well-established practices provide significant opportunities for career growth in SCM, showcasing a remarkable aspect of our company.

-

QPlease describe your career at Amorepacific in three words.

'Customer-Centric,' 'Driving force,' and 'Dynamic Capability'Despite being a manufacturing industry, the beauty industry is among the most rapidly changing sectors in the B2C market, driven by trends. The beauty and cosmetics industry maintains the closest engagement with customers, so we focus on developing customer-centric production technologies for SCM.

Moreover, we value the driving force and dynamic capabilities to relentlessly pursue and develop new production technologies. By seizing opportunities and identifying threats in the rapidly changing world, we continue to innovate according to market demands and introduce new technologies to proactively and promptly create products that meet customer needs.

-

QWhat is the most memorable or challenging experience at Amorepacific?

My most memorable experience was participating in the project that led to Amore Beauty Park in Osan being selected as a Global Lighthouse Network* by the World Economic Forum (WEF). Amorepacific became the first beauty company and the fourth domestic manufacturer to receive this honor. Being recognized as a Lighthouse factory confirms that we are heading in the right direction, feeling our efforts are finally paying off. As an SCM professional, I am proud that our production technologies are now on par with top global companies.

*Lighthouse factories are manufacturers that demonstrate leadership in implementing 4IR technologies on a large scale, driving significant improvements in financial performance, operations, and sustainability by transforming factories, value chains, and business models. The WEF and McKinsey & Company annually select these exemplary factories from manufacturing companies worldwide.

-

QWhat has been your happiest experience while working at Amorepacific? Also, what makes you dedicated to your work?

I feel most engaged in my work when I am growing within a relationship where my colleagues and I guide, learn from, and support each other.

Designing the factory site alone would have been impossible without my colleagues. Our accumulated technologies and the contributions of former employees have made it possible for us to join the WEF's Global Lighthouse Network.

Therefore, by learning from the work of senior colleagues and creating a supportive, caring environment together, I have achieved further innovation and progress through deep engagement.

-

QPlease introduce Amore Factory and the Botanic Garden located in your workplace, Amore Beauty Park.

Amore Factory is a special place designed to showcase Amorepacific's production philosophy and story, allowing visitors to experience our history and production process firsthand. As it is open to the public, we can share our journey, technologies, and dedication to our customers, making it my favorite site.

Amorepacific Botanic Garden, located in Amore Beauty Park, is home to about 1,400 plant species used as cosmetic ingredients. Other factories don't have a facility like this, and employees in the Beauty Park love it. During lunchtime, we appreciate the seasonal changes of nature and refresh ourselves while strolling in the garden. The garden feels like a source of comfort, especially when I face challenges.

-

QPlease tell us about your aspirations for a global vision.

Exploring changes in the world and discovering new technologies fuels my passion. I strive to continuously embrace, appreciate, and realize these changes.

I aspire to contribute to the global expansion of the company by providing the best products that meet customer needs worldwide.

Produce Beauty that

Captures Global Attention

SCM

We meticulously oversee every step of the process to ensure quality and safety.

With innovative systems and rigorous quality assurance, we swiftly deliver the highest quality beauty products to our global customers and strive for a sustainable future.

WE MAKE A MORE BEAUTIFUL WORLD

-

AMORE BEAUTY PARK

-

-

PRECISE QUALITY ASSURANCE

-

CONSTANT PROCESS IMPROVEMENT

-

-

SUSTAINABLE PRODUCTION

-

-

ECO-FRIENDLY SUPPLY SYSTEM FOR FUTURE

-

TOGETHER WITH COMMUNITIES

REALIZE YOUR DREAM AT AMOREPACIFIC

Exploring changes in the world and discovering new technologies fuels my passion.

Nahye Hwang, SCM

CREATE BEAUTY THAT CAPTIVATES THE WORLD

-

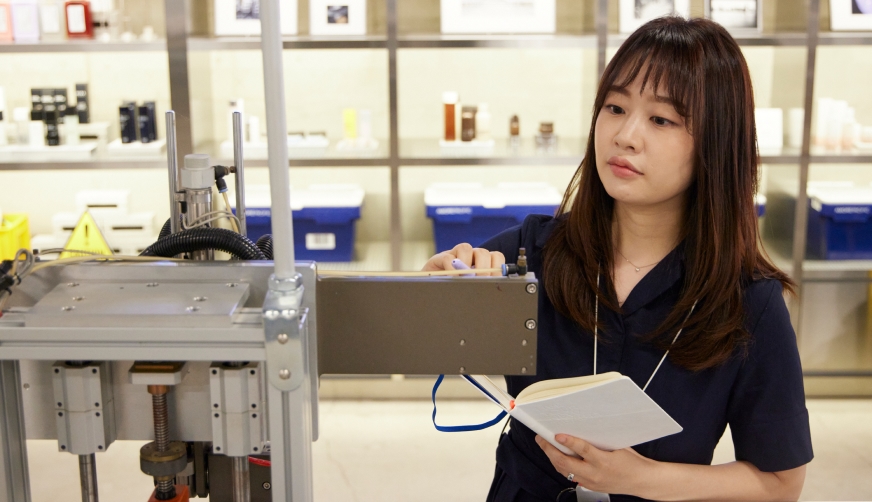

Our efficient logistics systems are established by using the latest technology and data. Through our innovative system, state-of-the-art automated facilities, and robust global infrastructure, the Logistics Management team provides our customers with reliable products.

-

For the safety and quality of our products, the Production Management team develops production technologies and smart infrastructure, while continuously refining production processes and optimizing facilities.

-

The Packaging Development team develops sustainable packaging by leveraging new technologies, staying informed on ESG regulations, and anticipating emerging trends. By consistently developing safe, high-quality packaging, our team ensures product integrity and stability.

-

Our management systems are rigorous to ensure the highest quality of products. This encompasses meticulous oversight from material procurement to product launch, substantial investment in research and development, and compliance with quality assurance policies.

OPEN SPACE TO CONNECT AND COMMUNICATE

Ignite collaboration, spark growth, boost motivation, and fuel innovative ideas.