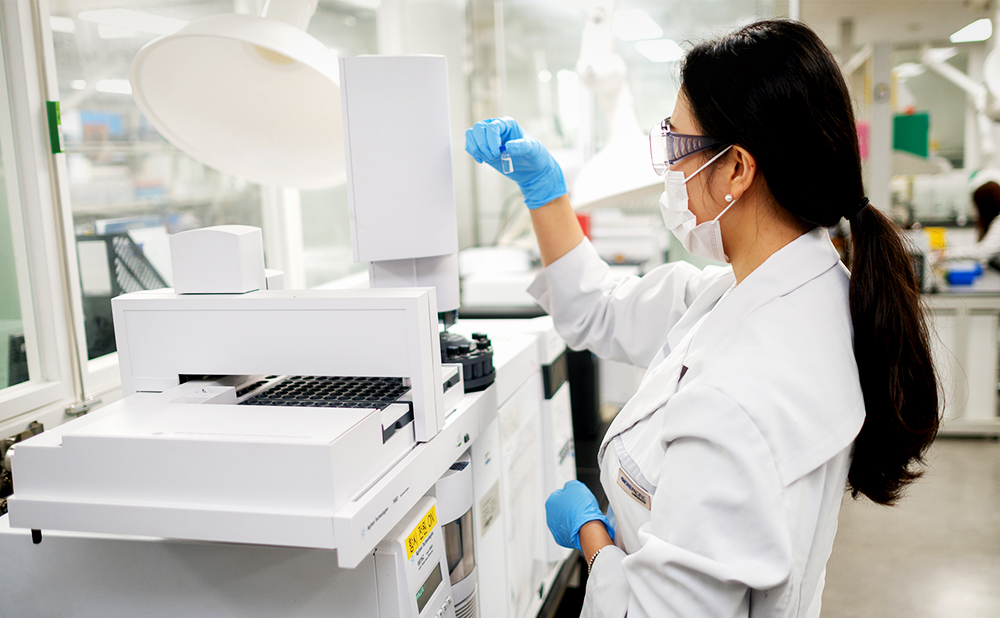

Customer Safety

Manufacturing Quality

Amorepacific deeply shares customers' concerns about human and environmental safety, and has established and applied rigorously our own global-leading quality standards.

Manufacturing Quality for Customer Safety

To secure customers's trust in the safety of our products, Amorepacific adheres to our own manufacturing quality standards with a focus on three pillars; safetry, efficacy and microbial safety. We also standardize criteria, improve expert capabilities and update quality test factors constantly for quality innovation.

Technology of Quality Innovation

Amorepacific has continued to innovate and develop its own unique manufacturing process to provide the best value for our customers and satisfy their needs. Amorepacific is pursuing digital transformation in its production process to achieve a customer centric ‘Smart SCM’ by digitalizing, connecting, and achieving autonomy in its supply chain. Through our effort, we will provide products with no defects so that our customers can feel safe to use.

Learn moreIntegration Process of Safety Quality

- Amorepacific safety standards for ingredients

- Local/global cosmetics/foods/drugs regulations

- Local/global safety/environmental chemicals regulations

- Specifications and testing certifications (certifications of analysis)

- Analysis and verification of quality/specifications of raw materials

- Raw materials safety testing: cell toxicity, irritation, allergy, eye irritation, phototoxicity

- Raw materials environmental safety testing: biodegradability, aquatic toxicity

- Additional certifications: natural/organic, vegan, CITES

- Amorepacific product quality standards

- Local/global cosmetics/foods/drugs regulations

- Global quality standards

- Implementation of usage preferences based on customer research

- Clinical tests on effectiveness and safety

- Safety test: dermatological clinical test, irritation and allergy testing

- Customer home-use tests for special benefits

- Amorepacific product quality standards

- Local/global cosmetics/foods/drugs regulations

- Global quality standards

- Implementation of usage preferences based on customer research

- Amorepacific packaging safety standards

- Quality and function tests of packaging materials

- Compatibility tests with formula

- Quality control tests and validation of ingredients on each lot

- Periodic and ad-hoc inspection of ingredient suppliers

- Quality management of raw materials

- Compliance with global GMP(Good Manufacturing Practices) standard

- Quality surveillance during production

- Quality control tests of finished products

- Additional stability and safety tests

- Customer use and sensory tests

- Compliance with global GMP(Good Manufacturing Practices) standard

- Quality surveillance during production

- Control of storage and shipping conditions to preserve integrity of products

- Management of optimal shipping conditions including damage prevention

- Thorough management of shelf-life or expiration date

- Integrated service for customer voices: real-time consultation and Q&A, VOC system and database management, customer claim analysis, self-collection inspection